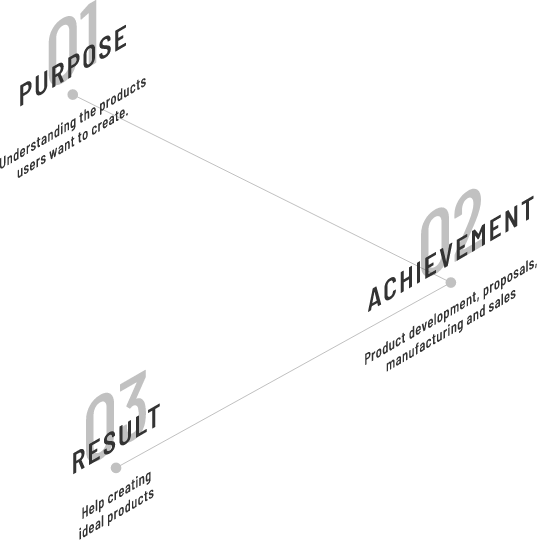

With experiences over 100 years in the field of wood coatings, supply paints that respond to detailed needs.

Propose production efficiency and quality improvements tailored that only a paint manufacturer can understand.

SERVICE 01 Manufacturing of paint

About product

Our trusted performance and quality built up over 100 years in the field of wood coatings

WASHIN’s paints have been developed with the aim of safety, ease of application and handling on the basis of our experience and technology accumulated over many years as a specialist manufacturer.

Our paints settle well with wood, have strong adhesion, durability, excellent color and provide a beautiful painted surface. Moreover, they are highly non-volatile and require fewer coats for a clean finish. A choice of paints is available to suit all situations, including open and closed finishes.

In addition to supplying paints that are friendly to the living areas, we also respond to detailed needs.

CASE STUDY 01 Sushi Aizawa Sushi restaurant

Washin Vietnam’s product was used for an interior project of a sushi restaurant in Ho Chi Minh City.

In a space, simply designed like a stage to enhance the beauty of the sushi, we painted especially on the black counter that connects the chef and customers

For the counter, we created a rough texture, which is smooth and comfortable, and added a new touch feeling to the sushi cultural place where sushi is passed from the chef to the customer

SUSHI AIZAWA

8/2 D. Le Thanh Ton, Ben Nghe, District 1, HCMC, Vietnam

INTERIOR DESIGN / PHOTOGRAPHY

NC1 Design Co., Ltd.

CASE STUDY 01 Sushi Aizawa Sushi restaurant

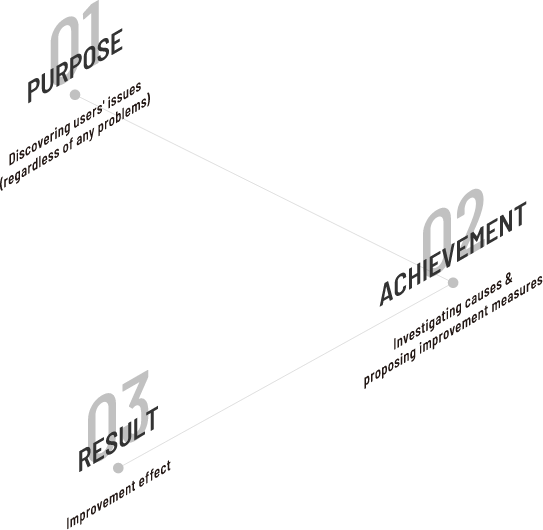

Service 02 Consulting about paint

About consulting

We propose improvements related to production efficiency

and quality improvement that only a paint manufacturer can understand